What Does Supply Chain Resilience Really Mean?

At its core, supply chain resilience is the ability to prepare for, respond to, and recover from unexpected events—be it a global pandemic, natural disaster, cyberattack, or supplier bankruptcy.

A resilient supply chain:

- Maintains operational flow during disruptions

- Recovers quickly when hit

- Adapts to new conditions with minimal friction

It’s not about predicting every possible threat—it’s about being ready even when you can’t.

Why Supply Chain Resilience Matters More Than Ever

According to a 2023 report by McKinsey, disruptions lasting more than a month now occur every 3.7 years, on average. And the costs? They’re steep. Companies stand to lose 45% of one year’s EBITDA over a decade due to supply chain shocks (McKinsey & Company, 2023).

Beyond financials, the reputational damage from supply shortages or delays can haunt brands long after the crisis fades. Customer loyalty is fragile—and once broken, hard to rebuild.

Key Strategies to Build a More Resilient Supply Chain

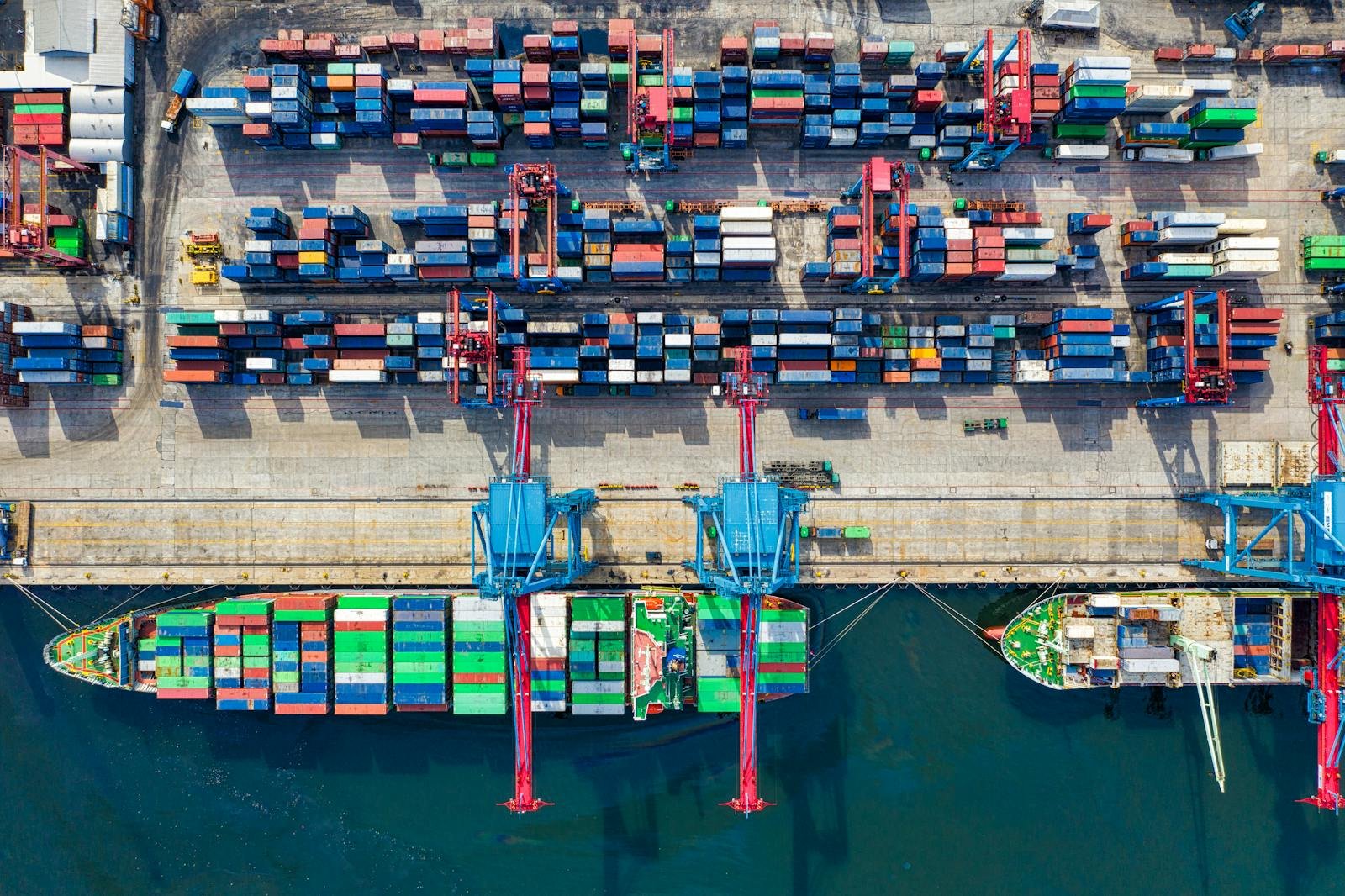

1. Diversify Your Supplier Base

Relying too heavily on a single supplier or region is a recipe for disaster. One hiccup—like a port closure or geopolitical tension—can derail your entire operation.

How to diversify:

- Source critical components from multiple regions

- Create a mix of local, nearshore, and offshore suppliers

- Develop relationships with backup vendors before you need them

💡 Pro Tip: Consider the “China+1” strategy—a growing trend where companies add a second country to their sourcing strategy alongside China.

2. Increase Supply Chain Visibility

You can’t respond to a disruption you can’t see coming. That’s where end-to-end visibility comes in.

Modern tools like IoT sensors, GPS tracking, and AI-driven dashboards allow you to monitor everything—from raw materials in transit to warehouse stock levels.

Benefits of better visibility:

- Real-time alerts when something goes wrong

- Faster decision-making during disruptions

- Improved demand forecasting and inventory planning

According to Gartner, companies that invest in supply chain visibility improve delivery performance by 20% or more (Gartner, 2022).

3. Build Strategic Inventory Buffers

Just-in-time (JIT) was once the gold standard. But in today’s unpredictable world, just-in-case (JIC) is making a comeback.

What to consider:

- Stockpile critical components with long lead times

- Keep safety stock for high-demand SKUs

- Balance carrying costs with potential downtime costs

Think of it like a savings account: it might not be exciting, but when disaster hits, you’ll be glad it’s there.

4. Digitize Your Supply Chain Operations

Still running key operations on spreadsheets? That’s a vulnerability.

Digital transformation helps you simulate different scenarios, analyze risk in real time, and make data-driven decisions quickly.

Consider using:

- Cloud-based ERP systems

- Predictive analytics tools

- AI-powered demand planning software

Companies with advanced digital supply chains were 2.5x more likely to outperform peers during the COVID-19 crisis (Deloitte, 2021).

5. Foster Cross-Functional Collaboration

A resilient supply chain isn’t built by logistics alone. It’s a team sport involving procurement, finance, IT, marketing, and more.

Collaboration tips:

- Break down silos with shared goals and KPIs

- Create cross-functional crisis response teams

- Align incentives across departments

When everyone’s rowing in the same direction, you’re more agile—and more prepared.

6. Embrace Scenario Planning & Simulations

Hope isn’t a strategy. But planning for “what ifs” is.

Use scenario planning to anticipate a range of disruptions—from supplier shutdowns to demand spikes—and rehearse your response.

Tools to use:

- Digital twins

- Monte Carlo simulations

- Risk heat maps

This isn’t paranoia—it’s preparation. And it pays off.

7. Strengthen Supplier Relationships

When things go south, strong partnerships matter.

Build trust by:

- Communicating regularly—not just when there’s a problem

- Offering incentives for transparency and performance

- Sharing forecasts and plans to help suppliers plan ahead

During COVID, many companies who had partner relationships instead of transactional ones saw better prioritization and flexibility from vendors.

Real-World Example: Toyota’s Earthquake Response

In 2011, an earthquake and tsunami in Japan crippled Toyota’s supply chain. Instead of scrambling, Toyota leaned into lessons from past disruptions.

They had already mapped 500+ suppliers across 6,000 parts. Within weeks, they stabilized production by reallocating inventory, leveraging alternate suppliers, and working collaboratively with vendors.

Fast forward to today—Toyota’s supply chain playbook has become a benchmark in resilience.

Conclusion: Future-Proofing Starts Now

Building a more resilient supply chain isn’t just a defensive move—it’s a strategic advantage. Companies that invest now will be the ones who stay ahead, no matter what the world throws their way.

Start small. Prioritize visibility, diversification, and collaboration. Use data as your compass. And above all—be proactive, not reactive.

Need help figuring out where to start? Consider a supply chain audit or talk with a logistics consultant. The sooner you begin, the stronger your foundation will be.

Frequently Asked Questions (FAQ)

Q1: What’s the first step to improving supply chain resilience?

A: Start with a risk assessment. Map your supply chain, identify bottlenecks, and evaluate dependency on single suppliers or regions.

Q2: How does technology help build a resilient supply chain?

A: Tools like predictive analytics, AI forecasting, and IoT sensors provide real-time visibility and smarter decision-making during disruptions.

Q3: Should companies return to just-in-time (JIT) or shift to just-in-case (JIC)?

A: It’s not either/or. A hybrid model works best—lean where possible, buffered where necessary.

Q4: How often should businesses review their supply chain strategy?

A: At least annually, and after any major disruption or change in demand patterns.

Q5: Can small businesses build resilient supply chains, or is it only for big corporations?

A: Absolutely. Even simple actions—like finding a second supplier or keeping buffer stock—can make a big difference.